Mike Costa, who’s experience in the Aerospace, Defense and Semiconductor industries would later lend itself well to a new start in the off road world as the creator of Closed System Winching. A system that provides winching with closed link hardware. Something no one has donesince the modern winch showed up on 4x4s in the early 70’s. Mike had an idea, the ProLink, his first product. Made of 6061 aluminum billet, it provides a lighter yet safer, closed system as opposed to a traditional hook and clasp. It’s designed to be used with a shackle which is five times stronger than the common winch hook. The ProLink has a hole at one end for attaching the shackle and a removable titanium pin at the the other end for attaching the winch rope eyelet. The pin stays secured in the ProLink using a retaining clip. The max load rating is 16,000 pounds. More than enough pulling power needed to recover heavy rigs out on the trails today.

He set off to the King of the Hammers event in Johnson Valley, CA with a backpack full of ProLinks. He showed his new idea to whoever would listen. Trudging from camp site to camp site, Mike showed off his new ProLinks and talked about their innovation, safety ratings and why the Closed System Winching was a safer bet versus the common hook found on all the rigs there. They listened and eventually he sold out of all that he had. He left King of the Hammers knowing he had something real and the Closed System Winching was born. The ProLink was just the beginning.

Fast forward to 2017. Factor55 attends a ton of shows during the year showing off their innovative products and has over 82k likes on their facebook page. Their products can be found on vehicles from the US Military, Special Forces, First Responders, I4WDTA, Ultra4 Racing and of course weekend warriors. Some of the top, winningest rock crawlers such as three time King of the Hammers winner Shannon Campbell use Factor55 equipment. Over 50,000 units sold and not one failure. In addition to the original ProLink, the FlatLink, The Splicer, and the UltraHook have further solidified Factor55 as being the leader in providing the best in recovery hardware. All of the aforementioned products reinforce the use of the proven screw-pin shackle which doesn’t allow the rope or cable to escape. Rounding out their product line is the Fast Fid synthetic rope splicer, various aluminum Hawse fairleads and the HitchLink which provides a lightweight, yet strong recovery point.

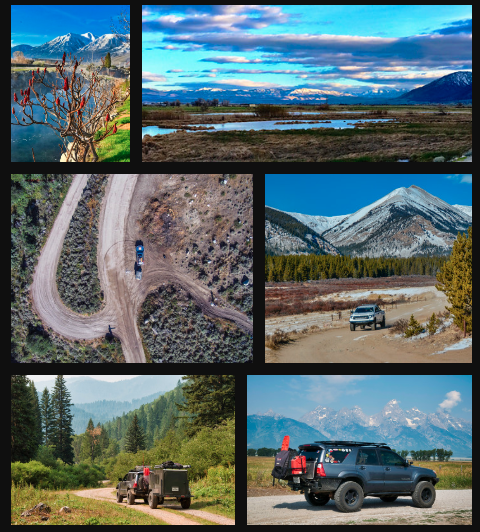

As we continued our shop tour with Mike we witnessed the meticulous details his products go through as they progress from a 3D cad program on the computer screen to transforming a small block of aluminum. Standing in front of the CNC machine, we saw Mike’s preverbial babies in various stages of being born. The robotic movements of cutting and milling bits inside the CNC machine gave life and purpose to the ProLinks. After milling the parts, precise instruments measure and test the tolerances. Another service puts on the final touches as protective coatings and finishes are applied. Each of their recovery products are also tested and stress analyzed with Cosmos finite element analysis (FEA). All of Factor55’s vendors are employed in the state of Idaho and are an important part of the success as products made in the United States.

[flickr set=72157684183286511]

To get your copy of theSpring 2017 Issue: |