Before we get started, let’s set the stage; we’re going to focus on 12 volt, consumer-grade electric winches for the purpose of light truck/SUV recovery. We’re not covering hydraulic and PTO winches in this article. The winches we’re discussing have planetary gear arrangements, use a “standard” mounting pattern, have some form of brake and will be sold more or less as kits ready to install & use. While this may seem over-generalized, these types of winches are what are most commonly encountered in there creational 4x4 world.

Don’t be B.A.D.

When selecting a winch, many people use the B.A.D. formula:

•Brand recognition (You’ve seen this product)

•Anecdotal (Somebody said it’s good)

•Display (It looks cool)

We’re injecting a little humor here, but is the B.A.D. formula actuallybad?

Maybe not, because:

•We can’t count out the well-known brands.

•We certainly can’t discount the experiences of others.

•Fit & finish are important to many people.

This article aims to get you thinking outside of the B.A.D. box and looking at some of the finer points of these electric winches. We’ll walk you through some of the terms and specifications that will better equip you to choose something suits your needs.

Pulling Power

You’ll notice that winches are often ranked by pulling power as their primary statistic. It’s measured in pounds, and you usually see them rounded off in 500’s or 1000’s. So how do we decide how much power we’ll need? The popular “equation” for choosing a winch is to choose a winch that is rated at 1.5x your vehicles’ GVWR* weight. For example, if you have a 5000lb vehicle, a winch rated forat least 7500lbs of pulling power should be sufficient.

About GVWR: GVWR (Gross Vehicle Weight Rating) seems easy enough, but I’m sometimes asked “What about GCWR**?” It’s a great question. Remember that GVWR is a rating. It’s a great guideline but it’s not your actual weight! If you can getyour fully loaded vehicle (and trailer, if applicable) weighed, you’ll have a very clear idea of what a winch is going to be working with. This is overkill for most folks.However, knowing your loaded weight can be eye-opening for you gear junkies who are pushing the limits.

Specifically Specifying Specifications

Not all winches are created equal! Many of them have competitive features but why is a 10k winch from Brand A costing $500 less than a 10k winch from Brand B? They might even be made in the same factory overseas for all we know!

Look deeper at the specs! A good winch manufacturer has nothing to hide, and will disclose the specs of the inner workings. If you can’t find the specs, ask or check in the manual. Many manufacturers have the manual available for download, for free, on their web site.

Here’s a walk through of what some of those specs are, and why they’re interesting to us.

Duty Cycle

Duty cycle is a percentage of run time versus cool down time. Simply put, how long your winch can run before it generates a potentially destructive amount of heat. Duty cycle depends on time and load.

A winch working near capacity for an extended amount of time will overheat faster than one that is simply spooling the rope in. You’ll probably never (at least, not at the current level of technology) see an electric winch with a 100% duty cycle. That’s stuff for hydraulic or PTO winches.

It’s worth noting that improper rigging can make your winch work harder than it needs to. It’s good to get some instruction on proper winching techniques to help preserve your investment.

Line Speed

Literally how fast it can pull --sometimes. There’s always a catch, isn’tthere?

The speed that it can spool in is going to be faster than its speed under load. Deceptive marketing practices can make a winch appear faster than it really is. When you read the specs, check the speeds under load vs. the speeds unloaded.

Faster isn’t necessarily better -- but it sure is nice! Fast winches can get away from you sometimes. Often, fast winches have a longer run-on* time. For most folks, slow is just fine.

*Run-on is the term for when the winch continues spooling after you take your finger off the button. It’s a natural state of affairs due to the way they’re designed. Some winches run-on longer than others. The longer the run-on time, the further you should keep your fingers from the fairlead!

Amp Draw

Electric winches work off of...electricity! I bet you didn’t see that coming.

•Where does that electricity come from? Your battery.

•What maintains your battery? Your alternator.

•What turns your alternator? Your engine.

While this seems rudimentary, it’s important to visualize the chain of power.

You’ve got this little piglet of an electric motor using engineering magic to pull thousands and thousands of pounds. It’s going to work hard. It’s going toget hungry. It’s going to eat a great deal of amperage from your battery. Your alternator is going to be pushed to maintain that battery.

The amperage draw rating gives you an idea of how efficiently your winch is going to operate. For short pulls, this isn’t as big of a deal but if you use your winch often, or in a professional capacity, it’s worth comparing what different winches offer. The more efficient, the better.

It’s worth mentioning that the winch motor will generate a great deal of heat as well – but we’ll get more into that a little later – read on!

Housing

The housing that the winch is assembled into is important. The housing houses the components such as the motor, gears and drum while also providing a mounting point at the same time.

Many winches these days are offered with cast aluminum housings. Someare machined. Machined housings are stronger. They’re also going to be more expensive.

Cast housings are weaker. They can shatter and break -- sometimes by tightening the mount bolts too tight (installation error) or by misuse. Be sure to follow the installation instructions carefully and always spool your winch rope on properly!

Solenoid / Control

Type You’re going to see two types: solenoids or contactors.

Most (not all) modern winches aren’t using solenoids -- they’re using contactors. Owners of older winches that use solenoids are upgrading to the modern Albright style contactors.

Albright type contactors are some what standard these days, and you should look for a winch that uses them -- preferably the Albright name brand. Depending on the model of Albright contactor, they can be IP67 water/dust proof. They’re also easy to find & replace should you have a problem outside of the warranty.

You’ll still see manufacturers referring to the control type as a “solenoid” even if it’s the newer Alright style of contactor. While it’s technically incorrect, it’s of no significance. Check the fine print!

Control Box

The “solenoid box” is properly named control box and is generally a housing for the solenoids or contactor(s) and their wiring, as well as that important plug for your wired controller. If there’s any wireless transceivers or other features, they’re usually inside the control box as well.

It's common to see the control box mounted on top of the winch. It’s a separate control box that can be re-oriented so things will fit different applications.

Sometimes, they are integrated into a water/dustproof housing that’s integrated with the winch housing. We refer to this as an integrated control box.

Related Articles

Your winch may not fit into your bumper with the separate control box attached, or with an integrated control box. It’s important to check the measurements and dimensions of the winch and bumper/mount before you purchase. If it won’t fit, you can sometimes relocate the control box.

Integrated control boxes aren’t intended to be relocated.

Separate control boxes can be relocated. Relocating the control box is pretty easy for beginners. Many companies offer a kit with instructions, longer wires, brackets and hardware for this task. If you’re concerned about the boxfitting, or you simply want to move it, check into this before purchasing.

Brakes

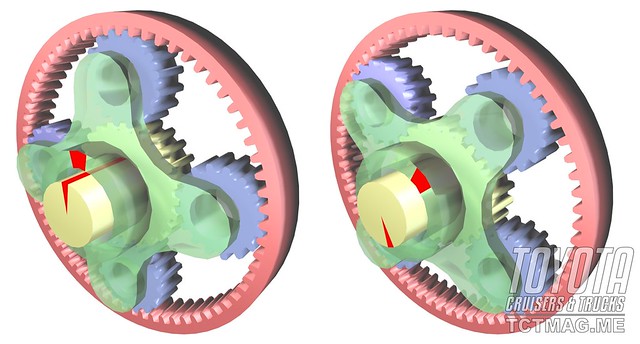

Most electric winches for off-road recovery have some form of dynamic braking. Dynamic braking means the brake is automatic and often holds only in one direction. You’ll run into a couple of different types of brakes, especially in planetary gear orientations.

Internal brakes are where the brake is located inside the drum. Since brakes generate heat, an internal brake can cause more heat inside the drum. This isn’t a problem with steel wire rope, but fitting synthetic winch rope to a winch with an internal brake can cause the rope to break down or melt on the drum. Some heat guards or sleeves on synthetic rope claim to negate this, but they too are made of a synthetic material.

External brakes locate the dynamic brake outside of the drum, and generate lower amounts of heat. Winches with external brakes are becoming more and more popular as synthetic winch ropes gain mainstream adoption.

Mechanical brakes are something you won’t run into as much these days, but winches such as the Warn 8274 are a great example of a one-way external mechanical brake.

Synthetic versus Wire Rope?

Point blank, I recommend a synthetic winch rope. Especially if you’re new to working with winches.

I intentionally cut straight to the chase there -- and that’s because there are numerous articles written by my colleagues and others that detail the differences, the pros and cons, and the nitty gritty of working with one over the other. I’ll give you an overview, but it’s by no means comprehensive and I urge you to research this well-documented topic on your own.

Synthetic winch rope is lighter and easier to handle. It’s easy to repair in the field (if you know how.) Under a load, it stores less energy than wire rope and is less apt to cause damage to people or vehicles in the event of a failure.

However, synthetic is prone to abrasion damage. It really doesn’t like heat, and it doesn’t take much heat to compromise its strength. It also doesn’t like UV light, which will degrade its strength over time.

If synthetic rope is not wound neatly on the winch drum, it can bunch up and damage the winch or pinch in between its own wraps, causing it to “reverse directions” in a pull. Mud, dirt and dust in synthetic winch rope can also wear it over time. While it can be washed, it’s tough to get all of the fine silt and grains out of it, which will abrade it over time & use.

Steel, on the other hand, is a great deal more resilient. It can drag over rocks, through mud and dirt and it’s going to handle it much better. It is, however, more of a tangle to work with. If it’s not wound on the drum properly, it quickly becomes a disorganized mess. It’s not easy to repair in the field without special tools & training. Lastly, it stores a great deal of energy and in the event of a failure, it’s a fast and deadly blur of whipping, razor sharp wires.

All that said, no matter which you choose, please get some training and practice with what you choose before you attempt anything serious with it.

Fairleads

Most winches come with a fairlead. The old, and partially incorrect method of deciding used to be “roller for steel, hawse for synthetic.” That doesn’t tell the whole story, though. There’s more to this, of course.

I prefer roller fairleads for my synthetic winch rope and I recommend the same. Rollers roll -- and as we discussed above, synthetic winch rope doesn’t like abrasion, friction and/or heat.

The cons on roller fairleads are that if they are damaged, they often stop rolling. They need some lubrication occasionally, especially if they are sitting outside. On some mounts or bumpers, they can stick out too much --reducing approach angles or sticking out too far, asking for damage.

In situations where you’re using synthetic winch rope but need as much clearance as possible, a hawse is a great choice.

While synthetic winch rope can be used with either hawse or roller fairleads, wire rope (steel cable) is generally shipped with a roller fairlead. While steel hawse fairleads do exist for use with wire rope, they’re usually a special order product.

Remote Control

Controlling an electric winch via a hand held controller is the standard way to operate one. They generally have some sort of rocker or joystick style switch which will spool the winch in or out. Some have lights, audible alarms and other features built into them. Nonetheless, they do a job and should be easy to operate. They should be waterproof and well built.

Wired controllers are most common, and my personal recommendation. Wires are quick to react and there’s no chance of RF interference. You should take care with the plug & pins on both the control box and the controller plug so that they aren’t bent, and are clean.

Wireless controllers have been around a few years, and have come a long way since the first ones hit the market. They offer the convenience of not having to connect a wired controller. There’s no control wire to get caught on things or trip over. The cons can be scary. My colleagues and myself have firsthand witnessed wireless-enabled winches start running by themselves. Haunting, for sure.

We’ve seen wireless controllers operate someone else’s winch. And then there’s that guy who lost his wireless controller, and didn’t have a wired controller as a backup. Don’t be that person.

Many (not all!) wireless controllers can be slow to react. They don’t always start when you want them to start and end when you want them to end. Some handle RF interference better than others, too.

Bottom line, I recommend wired controllers because they do what you tell them to do when you tell them to do it. They can often be repaired in the field. There’re no batteries to go dead. There’s no pairing process. They just work.

If you really want a wireless controller, I urge you to select a winch that also allows a wired controller to be used as a backup, and to carry that controller somewhere with you.

Foot Forward

Some bumpers or mounts require winches to be mounted foot-forward. This means that the “feet” or bottom mounting surfaces of the winch chassis are mounting forward, against the front plate of the bumper or mount. This is a great design, as the winch isn’t relying on bolts to hold it to the mount. The bolts simply hold the winch in place while the load is put on the bumper.

Not every winch can be mounted this way due to clearance. If the winch has a top mounted control box, thus making it “taller”, when oriented for foot forward it may not fit in the bumper. Find out what your bumper requires before you select your winch.

Clocking

The clutch lever is your best friend on a winch. Its job is to engage or disengage the gears in the winch. This allows you to pull winch rope off the drum by hand -- called “free spooling.” Free spooling is important because it allows you to spool line off while not adding more heat & wear to the drum and brake.

In some mounting points or bumpers, when the winch is mounted, the clutch lever cannot be accessed easily. Some bumpers offer a hole or slot in which to access the clutch lever. If you mount the winch, and the lever doesn’t lineup with the access hole, you probably need to clock the winch.

Clocking is a term for when you unbolt the gear housing from the winch assembly and rotate it in a way to reorient the clutch lever where it can be easily accessed. Because most of these winches are planetary gear arrangements, there’s more freedom to rotate the position of the housing. Most winches you’ll run into can be clocked, and instructions are provided in the manual on how to do this. It’s quite common. Be sure to check the specs & manual before you purchase.

Warranties

I always say:warranties only work in your driveway. The warranty department of the winch manufacturer isn’t going to be found flying out to you on the trail in a Chinook helicopter to recover your vehicle and happily replace the winch while you have a sandwich and watch them work.

A good warranty is important, but it doesn’t make an inferior product superior. If it’s a poor-quality product, it will let you down and it will be at the worst time. When you’re stuck in the middle of nowhere, unable to recover yourself, a painful reflection on how great the warranty is will not improve your state of mind.

Everything has a warranty these days, and most big-name winch manufacturers are good about support. Good quality products, known to be reliable and well made, are less apt to need that warranty, so choose wisely.

Other Features

There’s a good deal of other features we’re seeing crammed into winches these days. Compressors, bluetooth controlled via phone app, over heat warning lights and buzzers, espresso makers...wait. I was joking about the espresso maker. Honestly, it wouldn’t surprise me these days.

All comedy aside, the number of features can be overwhelming, and at times, useless.

You might not need (or want) bells & whistles. You might only use the winch a few times a year. You might not have a huge budget for something that is rarely used, but you don’t want to be without. Sometimes, the most basic piece of machinery is the best. It’s easy to get lost in features. Keep your feet on the ground and don’t get caught up in the marketing hype.

Conclusion

There are a great many details hidden in the specs sheet of a winch. Wrapping your head around them not only helps you become a better winch buyer -- it makes you a better winch operator. You’re gaining understanding of how this piece of equipment works so that you can better apply it to a situation where it’s needed.

I wish the best to you in your winching endeavors. Work safe, work smart, and don’t forget to put your gloves on!

To get your copy of the

Winter 2020 Issue:

Follow us on Facebook, Twitter, and Instagram to get up-to-date industry news, events, and of course, amazing adventures, stories, and photos!